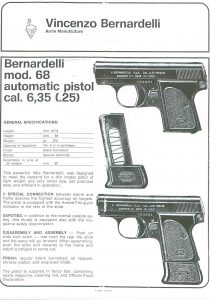

The opportunity is given today to write on the gun mod 68 or “Baby” V.Bernardelli.The weapon that I present to you is in gauge: 6.35 mm or 25 acp.

I wanted to talk about this weapon because I did not expect to find such a beautiful finish on a weapon of this type, namely: a small defense gun. The second reason for writing this article is the mounting of the barrel on the carcass. This one is not very current and very well executed, it deserves that one pays there also.

Characteristics of Bernardelli Baby

I will not go back on the history of this weapon because I do not have any elements on the question. It seems that the first models appeared in the years 1940/50. You can find the history of the firm V.Bernardelli, by clicking on the logo of the brand.

There is a version of this weapon in 22 caliber shorts. It would have been useful to compare the two models in order to relate commonalities and differences. I was not allowed to combine the two versions at one time. Therefore, I can not do this comparison today. The future will give me the opportunity to do this experience later.

There is a version of this weapon in 22 caliber shorts. It would have been useful to compare the two models in order to relate commonalities and differences. I was not allowed to combine the two versions at one time. Therefore, I can not do this comparison today. The future will give me the opportunity to do this experience later.

- Length of the weapon: 106.5 mm;

- Length of the weapon: 106.5 mm, Height of the weapon: 69 mm (with the 5-cartridge magazine), 68.5 mm (without magazine);

- Thickness of the weapon: 20.5 mm;

- Mass of the weapon: 260 grams (with the charger 5 shots empty);

- Barrel length: 53 mm;

- Caliber: 6, 35 mm Browning or 25 acp;

- Number of shots: 5 to 8 depending on the magazine (here, 5-cartridge magazine);

- Type of mechanism: single action;

- Safety lever on the left side of the carcass;

- Charger security;

- The grip is good but the weapon is low volume;

- The weapon is entirely made of steel (except the butt pads);

- Number of rooms: 39.

User disassembly of the Bernardelli Baby:

The user disassembly of this weapon does not require any special tools. The different steps to accomplish this task are detailed below:

- Handling a weapon can cause serious damage. Therefore: Always point the weapon in a direction that is not dangerous to you or others, check that the weapon is not supplied (no charger engaged) and that the chamber is empty;

- Remove the magazine from the weapon;

- Check that the chamber is empty;

-

By checking that the chamber is empty, it is likely that you have armed the striker (it all depends on the length of the rear stroke that you make the bolt). It takes a race of the breech 23 mm back to arm the firing pin. It can be seen that the firing pin is in the cocked position when a small pointed piece projects at the rear of the bolt;

- Press the button on the back of the frame on the left side of the weapon;

- Whatever the position of the firing pin, (armed or unarmed) the assembly lever will be extracted from its housing under the pressure of the firing pin spring and the trigger spring;

-

Push the striker spring back into the breech. To do this, you must, if the firing pin was armed during subsequent manipulations, engage an empty magazine (just enough to disengage the magazine security from the trigger, see the next picture) and squeeze the trigger (d where the interest of having checked if the room is empty);

- Remove the charger again;

- Pull the cylinder head a few millimeters backwards to disengage the extractor from its housing;

- As you have disengaged the puller, lift the back of the bolt;

- When lifting the rear of the cylinder head, be careful not to lose the separator. He only asks to leave. We will see later the role of this piece.

- Under the action of the recovery spring the breech will leave its housing forward. Accompany the breech in its movement. Be careful not to lose the separator, the striker spring, the striker, the recuperator spring and its guide;

- To dismount the barrel, extract it by pushing it on the left (on my copy, it leaves on the left);

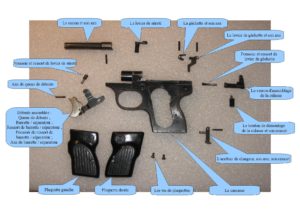

- User disassembly is complete, you get the following items;

The subsets of the Bernardelli Baby

The subsets of the Bernardelli Baby pistol in 6.35 mm are:

- The breech / barrel subassembly;

- The carcass subassembly;

- The charger subassembly.

Let’s detail each of these subsets.

The breech / barrel subassembly

The breech / barrel subassembly of the studied weapon is composed of 11 pieces:

- The breech;

- The extractor;

- The extractor spring;

- The axis of the extractor;

- The Canon ;

- The recovery spring;

- The guide rod;

- The striker;

- The striker spring;

- The guide of the striker spring / armed witness of the striker;

- The return spring of the armed indicator of the firing pin.

The cylinder head is made of steel. It enters a volume of: 15.4 mm (width) x 21.5 mm (height) x 104 mm (length). The mass of the piece (with the extractor) is: 72 grams. The distance separating the bottom of the breech (or the top of the carcass) and the axis of the barrel is: 4.5 mm.

The diameter of the firing bowl (housing of the base of the case in the cylinder head) is: 8 mm for a depth of: 0.94 mm.

The maximum stroke of the barrel in the breech (same with or without a recuperating spring) is: 28 mm whereas an ammunition measures approximately 22.8 mm.

The “gunsmith” disassembly of the parts constituting the cylinder head consists in driving the axis of the extractor from its housing by means of a 1.5 mm pin punch. The axis is fine and short. The extractor spring is 3 mm long and has a diameter slightly less than 3 mm. These pieces are small: be careful not to lose them. Disassembling these parts should cause you to properly clean the extractor housing. We do not often have access to this site, so it’s an opportunity to do things right. Clean the parts also before reassembly.

The diameter of the striker body is: 5.96 mm. The diameter of the striker tip is: 2 mm. The total length of the firing pin is: 19.5 mm. It would be interesting to compare the striker of the version in 6.35 mm and that of the version in 22 short. Indeed, the percussion of an annular cartridge of caliber 22 short requires, so that there is percussion, to come to hit the bead of the holster. In this case, it seems that two solutions arise for us:

- Either bring the diameter of the striker body to 7 mm (diameter of the bead of an annular short cartridge 22) to then locate the tip of the striker at the periphery of the cylinder of diameter 7 mm;

- Or eccentrate the housing of the firing pin;

- See both solutions at the same time.

What choice did the manufacturer make? To date, I do not have the exact answer to the question because I do not have access to the dimensions of the piece in shorts. An exploded view of the short version, however, helps us in our reflection. We can see on the exploded below the form of the striker but also that the ejection is not operate by the striker itself but by the extension of the guide rod of the striker spring.

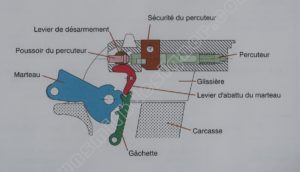

The cylinder head does not move on the carcass via machined rails as on most automatic guns. The guide of the cylinder head is made in two points:

- The first guide is the barrel, the front of the bolt slides around the barrel;

-

The second is the assembly lever. The latter penetrating into the housing of the striker limits the movements of the breech.

After percussion, a rear stroke of 23 mm is required at the bolt for the striker to be cocked again. The firing pin of the firing pin does not protrude from below the bolt. It is the trigger that comes to “look” in its path. The firing pin serves as an ejector. At the end of the race of the breech, the point of the striker protrudes by 3.6 mm in the bowl of firing, which gives an impulse to the case which pivots around the extractor and ejects.

The barrel enters a volume of: 53 mm (length) x 11.7 mm (width) X 14.4 mm (height). The outer diameter of the round party is: 9.8 mm. The mass of the barrel is: 21 gram. The bead of the cartridge remains outside the chamber.

Was the barrel scratched after machining its profile? Or, did the scratching take place first and then the machining of the profile? This would be interesting information to know. I would go for the second solution (because the most common). Namely: the use of steel rod of several tens of centimeters drilled and scratched to the caliber 6.35 mm. The bars are cut to the desired length. The profile of the barrel is obtained by machining these portions of bars. Then the room is made with a specific strawberry (strawberry room). The barrel of the Bernardelli baby can be obtained from a strip of 14 mm diameter bar (minimum). The barrel has 6 scratches on the left.

One of the important things about this weapon is the method of assembly chosen by the manufacturer V.Bernardelli to bind the barrel and the carcass. Indeed, this type of assembly is little used. The barrel is held on the carcass via an inverted T-shaped fit. The barrel enters laterally in a groove made in the carcass. The machining does not present simple shapes: that is to say rectangular (what one would expect) but are rounded shapes. If the machining of the female housing requires a milling cutter, the male form requires more complex machining and fitting. I think this choice is a desire of the manufacturer to avoid the appearance of cracks in the corners (especially the upper corners) if a rectangular geometric shape had been chosen. The adjustment on the weapon at my disposal is particularly well done, the barrel once on the carcass has only a very weak game.

The width of the T branch is: 11 mm. The height of the T branch is: 2 mm.

The recovery spring has a length of: 55 mm. The diameter of the wire is 0.7 mm. The spring is flared at both ends. In the center, the outside diameter is: 5.7 mm. The flares have an outside diameter of: 6.6 mm.

The guide rod has a length of: 53.6 mm for a body diameter of: 4 mm.

The slide on mine does not go back far enough to cock the pistol. what may be wrong? How do I fix this.

Bonjour,

It s not easy to answer without see the gun in hands.

May be the munition is too slow.

Your faitfully.

Cédric.

I had exactly the same question about my pistol. The slide didn’t seem to go back far enough to allow the striker catch to engage with the sear. But this was a misunderstanding. The real problem was that the separator (more commonly called the disconnector) was missing. As the instructions above warn us, this part is very easy to lose. This caused the trigger to always be disconnected from the striker. Once I found it and reinstalled it, the pistol worked normally.

I had exactly the same question about my pistol. The slide didn’t seem to go back far enough to allow the striker catch to engage with the sear. But this was a misunderstanding. The real problem was that the separator (commonly called the disconnector) was missing. As the instructions above warn us, this part is easy to lose! This caused the trigger to always be disconnected from the striker. Once I found it and reinstalled it, the pistol worked normally.

Per favore mi interessano dei ricambi per calibro 6.35 bernadelli modello 68 mi servirebbe il precursore completo della molla è tutto il kit che va con il precursore e la molla di ritorno