Some information is difficult to find because it is poorly documented. Either they have no interest or nobody has thought to put this information in shape and available to the general public. Let me introduce you to one of these little-known information, namely, how was the gun of a Fein 65 (airgun) mounted on the carcass?

Having on hand a copy of this weapon in average condition, I took the opportunity to answer this question.

The dismantling of the barrel

Before attempting a particular dismantling method, one must define what is considered to be the method of mounting the barrel. Possible editing modes:

- Screwed;

- Inserted in force;

- Pinned;

- Pasted;

- Welded (unlikely here);

- Several of the solutions cited above;

- …

About me, having no certainty. I hesitate between several choices (press fitting or screwing). I’m considering two options:

- Pass the barrel to the press and try to extract it to the front. If the barrel is screwed on the receiver, I may damage the parts by tearing the thread;

- Machine the receiver to remove all or part of the tension around the barrel and see if the barrel is, or not, screwed into the receiver. It’s a destructive way.

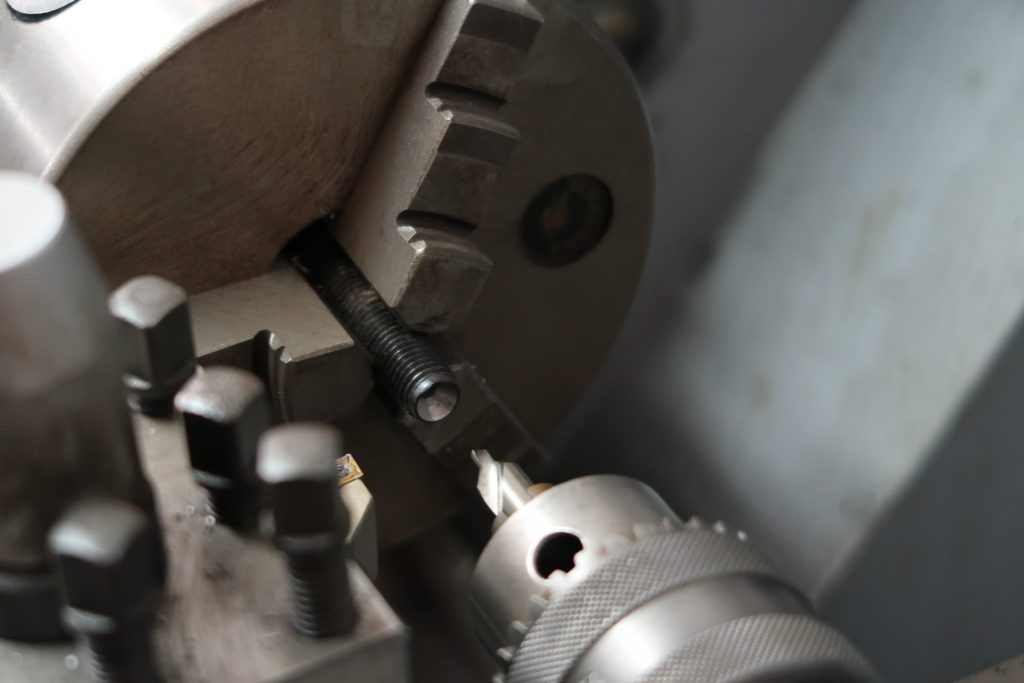

I decide to test the first option. If it does not work, fall back on the second. To do this :

- I drilled a steel plate about 10 mm thick with a 13 mm diameter forest. She will serve me as a breech box stopper;

- Realization of the housing of the barrel on the gun pusher (the barrel being conical);

- Presentation of the assembly on the press;

- Following the first pressurization, it turns out that the pusher is not suitable. The first pusher is a car bolt. The latter was twisted by the effort of the press (see photo below). The second pusher used is a full steel bar with a diameter of 20 mm.

- With this new push, the effort of the press has fully applied to the barrel. After a snap, the barrel came out of its slot. The snap is due to the breakage of two steel circlips.

- At the sight of these circlips, it seems that the barrel is mounted by pushing it from inside the box of breech. So, I had to disassemble it by pushing it towards the inside of the box of breech. Which would not have broken the circlips.

- The barrel housing on the receiver is clean. The diameter of the barrel housing in the receiver is 13 mm. The breakage of the two circlips (barrel stop on the receiver) did not damage the barrel housing.

A possible continuation

What could be the continuation of this article? It would be quite interesting:

- To make a thread on the box of breech and to raise various cannons. We could then test a Fein 65 in caliber 5.5 mm or 6.35 mm, for example. Whereas the housing of the barrel on the receiver is: 13 mm. The retained thread could be 14 x 100;

- To see if the volume of compressed air produced by the original mechanism is sufficient to propel a projectile larger and heavier than the original projectile?

- To make speed measurements of the different calibres for different gun lengths?

- To mount guns longer to test if the volume of air is sufficient;

- If the tests proved conclusive, it would then be possible to decline the Fein 65 in a rifle version with compressed air …, see take down air rifle;

- To consider this method of disassembly to replace a worn barrel and thus repackage Fein 65 shooting club;

- To dismount a second Fein 65 but this time by pushing the barrel towards the inside of the box of breech to compare the two methods;

- …

Tell me about your ideas, help me extend this list, send me an email at:

contact@gunsmithdesigner.com