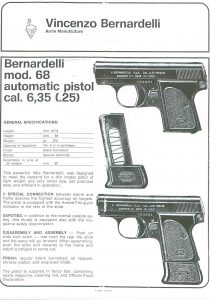

This second article on the Bernardelli baby pistol is the sequel to the first, published a few weeks ago. The following chapters will deal with the carcass, the description of the successive stages of a shot start, the loader, the shot with the Baby pistol and the conclusion. Good reading …

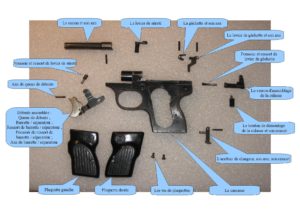

The frame

The frame subassembly is composed of 23 parts:

- The frame ;

- The left grip ;

- The right grip ;

- The screw’s grip ;

- The lever savety’s spring ;

- The lever savety ;

- The trigger bar ;

- The trigger ;

- The sear ;

- The pin’s sear ;

- The magazine safety ;

- The pin’s magazine safety ;

- The lever assembly ;

- The spring and push of lever assembly ;

- The slide bolt catch ;

- The slide bolt catch’s spring ;

- The pin of the magazne catch ;

- The magazine catch ;

- The return lever of the trigger tail ;

- The magazine catch’s spring.

Gunsmith disassembly of the carcass

The dismounting “gunsmith” of the carcass is pleasant to do because several operations do not require tools. The only useful tools are a screwdriver and a pin punch 1.5 to 2 mm in diameter. Here are the steps:

-

-

- Remove the separator ;

- Using a screwdriver, remove the right and left stick pads (be careful not to lose the safety lever spring in the left pad) ;

- Remove the safety lever ;

- Remove the trigger bar ;

- Remove the trigger ;

- Using a pin punch with a diameter of 1.5 to 2 mm, extract the trigger pin.

You can then disassemble: the trigger, the assembly lever, the assembly lever spring and push, the assembly lever lock, the assembly lever lock spring ;

- Using the same-hunting pin, extract the loader safety pin and disassemble the loader safety ;

- The last action is to come to hunt, always with the same punch-pin, the charger lock pin.

At the end of these steps, the weapon is completely dismantled.

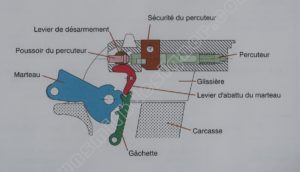

The trigger and sear mechanism

The mechanism has few parts. Although small in size, they are well machined and adjusted.

Some machining of the carcass are complex including the housing of the trigger. The thickness of the walls of the feeder well are fine (1.2 and 1.36 mm). And yet the pieces are terribly well finished.

The operation of the magazine safety: the latter pivots around an axis and is driven by a small spring. When the loader is not present, the loader safety tilts under the action of its spring and prevents the movement of the trigger tail. In the event that the spring of the magazine safety is broken and / or it is difficult to find one, it can be considered to temporarily remove the loader safety of the weapon (disassembly is explained in the previous chapter) in order to continue using it the time to get the missing items. The removal of this piece does not prevent the weapon from functioning. However, we must not forget that a security has been removed and so that it can change your habits.

What happens when the shooter presses the trigger, (take the case where a magazine is engaged, the striker is armed, the breech is closed, a munition is chambered):

- The shooter presses the trigger. By pressing the trigger, the shooter moves the bar back. The two pieces are connected to each other;

- The bar being in contact with the return lever of the trigger tail, it pivots about its axis. The return lever of the trigger tail is moved by the force of the common spring loader lock;

- Moving the trigger lever of the trigger tail back releases the trigger. Indeed, this part is a lock for the trigger, it prevents it from going down and thus release the striker in various circumstances.In other words: after a certain stroke of trigger, the trigger is no longer locked;

- The shooter continues his action on the tail of relaxation.The back of the bar comes into contact with the trigger and forces it to turn (down) about its axis;

- After some relaxation tail stroke, the striker is released;

- The striker spring relaxes;

- Under the action of the striker spring, the striker is launched on the primer of the cartridge;

- The primer is struck, the flame produced ignites the powder;

- Under the action of the gases produced by the powder of the cartridge, the walls of the case expands and sticks against the walls of the chamber, there is sealing;

- The ammo leaves its location in the cartridge case.The warhead comes out of the barrel;

- The impulse produced by the expansion of the gases is channeled through the barrel. It acts on one side on the projectile and on the other side on the case of the cartridge and the breech;

- Once the warhead comes out of the barrel, the internal pressure drops. The case retracts, it no longer sticks to the room;

- The energy gained by the breech breaks the inertia of the breech. The breech begins to retreat;

- About 7 mm after the start of opening, the separator lowers and disengages the trigger from the grip of the bar;

- The released trigger returns to its high position under the action of its spring;

- Ejection of the drawn socket;

- Pushed by the lifting board and the magazine spring, the next ammunition of the magazine takes its place on the lips of the magazine;

- The armor of the firing pin protrudes beyond the arm’s length of the trigger, when the firing pin is armed;

- The recoil of the breech is damped by the recuperating spring;

- The recuperating spring decompresses, the breech begins its race forward;

- A new ammunition is pushed towards the room;

- The striker is held back by the trigger;

- At the end of the cylinder head closure, the separator resumes its place under the action of the return lever of the trigger tail;

- Returning forward the return lever of the detent tail causes the bar to go up and thus back to the contact of the trigger;

- The shooter releases the pressure on the trigger tail;

- The bar resumes its place;

- The weapon is ready to repeat the same cycle if the shooter presses the trigger tail again.

The magazineThis subset is composed of 05 pieces:

- The magazine body;

- The lifting board spring;

- The lifting board;

- The magazine bottom lock;

- The charger bottom.

The magazine is a sheet that has been stamped and welded. It is surprising to see that the weld is not located at the back but on the left side. This is unusual especially since the Baby gun magazine has side openings. The piece is perfectly made and has not suffered from past uses. The welding is fine and not very visible, it shows no sign of weakness. The location of the side openings is clearly not a problem for the weld.

There are two types of magazine for this weapon. A version in 5 moves and one in 8 moves. The latest version protrudes from the weapon and acts as a handle extension. The addition brings greater comfort to the user but gives a little more volume to the weapon. We can not have everything.

Few people completely and regularly dismantle the magazine of their weapon. It is a mistake because this cleaning allows to remove any kind of deposit, such as: dust pile, stuffed animals, firing residues, oil … which can at some point block the lifting board and make it inoperative. food. What’s more useless than a defensive gun that does not work when you need it. If you do not do the disassembling and cleaning yourself, have a conscientious connoisseur do it better to see a professional.

You will find below the operating mode for the disassembly of the charger:

- Using a tool, push the magazine bottom lock into the interior;

- Push the feeder bottom towards the front of the feeder;

- Remove the loader bottom completely, taking care to hold the loader bottom lock and the spring of the lifting board;

- Remove the lifting board and its spring;

Pay attention to the disassembly direction so as not to make mistakes during reassembly.

On the model at my disposal, the lifting board has side flanges that improve the guidance. The part seems to be executed by stamping a flat sheet.

The shot Bernardelli Baby

Shooting with this small weapon is very nice. The recoil is small, equivalent to shooting a 22 Lr ammunition in a similar weapon. The accuracy has not been tested for lack of available ammunition and the weapon is not really intended for marksmanship.

The average pressure of a 6.35 mm cartridge is 1300 bar (source: CIP standard). The test pressure: 1690 bar (source: CIP standard). For a ball weight of: 3.2 grams, a speed of: 200 meters per second this gives us a warhead energy of: 70 joules (Fiocchi catalog).

The power of stopping the 6.35 mm is not enough to stop the attacks of a decided individual. Even less if he is under the influence of narcotics or in a state of delirium. The interest of the weapon is its very small volume but not its stopping power. In some ways, it can be reassuring to have this type of defense weapon in your pocket (if the regulations allow you) but it must be borne in mind that it will not necessarily be enough to get you out of bad situations.

Conclusion

It should not be easy to machine small parts in series. V.Bernardelli’s Baby pistol is nevertheless very well done. No traces of machining are visible. Industrial choices are bold but mastered. The aesthetics is very nice. The weapon is well proportioned and well balanced.

It would be very interesting to compare the weight of the cylinder heads, the strength of the recovery spring of the versions in 22 short and 6.35 mm to relate these data with the average pressure and the ball weight of the two calibers mentioned. This would make it possible to determine a typical breech weight, a standard barrel length, a typical spring recovery force for a given caliber and then compare them again with data from other manufacturers. If you have this information, they interest me.

The realization of a “torture test” and the analysis of the results provide a lot of information on the design and life of a weapon. While the latter is not intended for intensive shooting, what would be the behavior of the Baby gun during a torture test? After how much ammunition fired would the first piece break? What would be the first cased pieces? Are the same pieces breaking at the same time? How to cure it ? To this day, I do not know if the firm Bernardelli performed this kind of test for this weapon. It would be interesting to have access to the results of one of these tests.

The choices of the designers, the validators of these choices are of great importance. Good technical choices will allow the weapon to become an icon of its category and to go through the years to become a timeless object. The design, the realization, the promotion, the marketing are deeply linked stages which, if they are successful, will anchor a weapon in the thoughts. We will find this weapon many years after its manufacture always in working order (because well designed), always pleasant to look at or use. Time will give it a charming patina and a greater value. I think the Baby gun is one of them.

-